Advancing Heat Pump Efficiency with PCM Thermal Storage: Insights from the HYSTORE Project

The integration of Phase Change Material (PCM) thermal storage into heat pump systems offers transformative potential for energy efficiency and compactness. A recent study, conducted under the HYSTORE project and published in Applied Thermal Engineering, presents a breakthrough design for PCM-enhanced thermal storage modules specifically tailored for heat pump cycles. Below are the key findings and implications of this research.

Innovative Design Approach

The study introduces a compact PCM thermal storage module built using aluminum Micro Port Extrusion (MPE) tubes brazed with fins and filled with PCM. This design addresses critical challenges in heat pump systems:

-

Compactness: The module achieves a PCM volume fraction of 75%, significantly surpassing the 48% achieved by conventional plate-and-bar geometries.

-

Cost Efficiency: MPE tubes reduce manufacturing costs while maintaining high heat transfer rates, making the design economically viable.

The module functions as a desuperheater, utilizing the high-temperature refrigerant gas phase to generate Domestic Hot Water (DHW). This configuration minimizes reliance on electric backup heaters, thereby improving overall system efficiency.

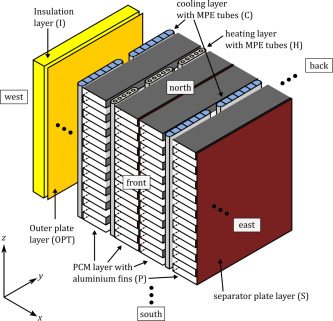

Fig. 1. Detailed section of a PCM storage with a MPE tube-fin HEX. Note that, insulation (I, yellow) and the container/outer-plates (OPT, orange) are only sketched on the west side but are considered in the simulations on all six surrounding surfaces. In the x-direction one sees different layers of material, in the y-direction the MPE tubes are evenly distributed within a layer and the HTF flows in the z-direction. Please note that this figure represents only a detail section from a larger storage that only serves to explain the models.

Computational Modeling Innovations

To optimize the storage design, researchers developed reduced numerical models using Modelica, enabling rapid simulations of heat transfer dynamics. Key achievements include:

-

Simulation Speed: The reduced Modelica models were 33,000 times faster than traditional Computational Fluid Dynamics (CFD) methods, allowing efficient parameter optimization.

-

Accuracy: Predictions of heat transfer rates, charging/discharging times, and temperature distributions closely matched experimental results.

These computational advancements facilitate automated design optimization, reducing development time and costs.

Experimental Validation

The study validated the PCM storage module using a propane-based heat pump test rig with 250 g refrigerant charge and commercial PCM RT55. Results demonstrated:

-

Energy Savings: Electricity consumption was reduced by 3.3–5.2% compared to conventional systems.

-

Performance Reliability: Experimental data confirmed the accuracy of Modelica predictions, ensuring real-world applicability.

Implications for Heat Pump Technology

This research aligns with HYSTORE’s mission to enhance renewable energy systems through advanced thermal storage solutions. The optimized PCM storage design offers several benefits:

-

Scalability: Suitable for residential and commercial applications, particularly in space-constrained environments.

-

Demand-Side Management (DSM): Enables load-shifting to benefit from variable electricity pricing or renewable energy availability.

-

Environmental Impact: Compatible with low-GWP refrigerants like R32, supporting decarbonization efforts.

Future Directions

The study highlights avenues for further innovation:

-

Exploring cost-effective PCMs to lower manufacturing expenses.

-

Integrating PCM storage with photovoltaic systems to maximize renewable energy self-consumption.

-

Expanding applications to include space heating/cooling alongside DHW production.

The HYSTORE project’s research demonstrates how PCM-enhanced thermal storage can revolutionize heat pump technology by improving efficiency, compactness, and affordability. With its scalable design and environmental benefits, this innovation represents a significant step toward achieving sustainable energy goals in building heating and cooling systems.