HYSTORE presents: Asmaa Ali, R&D Engineer

Developing tailored phase change materials (PCM) and achieving optimal system performance are key enablers for advancing thermal energy storage (TES) technologies.

A phase change material is a substance able to release and/or absorb energy when a phase transition occurs (usually from solid to liquid and vice versa). This enables it to provide heating or cooling, depending on the needs. PCMs can be organic or inorganic based. PCM plays a vital role in the efficient storage and release of heat in thermal batteries, and thermal energy storage systems, as well as in diverse applications such as heating and cooling in buildings, pharmaceutical logistics, automotive industries, etc.

Meet Asmaa Ali from Rubitherm® Technologies

Asmaa Ali has been working as an R&D Engineer at Rubitherm Technologies since August 2021. She studied Materials Science during her master’s degree after obtaining a Bachelor of Science in Chemistry and Physics.

What is the role of Rubitherm® Technologies in the project?

Rubitherm® Technologies is the manufacturer and supplier of both organic and inorganic PCMs that are going to be used in 3 out of 4 HYSTORE solutions. Besides, the team is also involved in setting up a modular storage designing the heat exchanger, the storage tank, and setting technical specifications.

How would you describe the impact that PCM can make in Thermal Energy Storage (TES) and more specifically in HYSTORE?

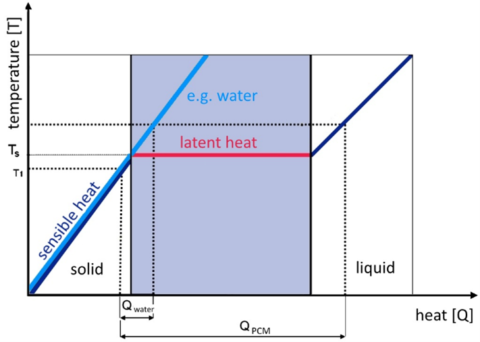

PCM is a material with significant potential in advancing the TES sector. Among its advantages, it is very efficient in storing and releasing heat within a narrow temperature range. During the phase change, absorbed heat is used to drive the transition from liquid to solid while the temperature of the PCM remains constant. Once, the PCM has fully transitioned to a liquid state, further heating causes the temperature to rise again. When freezing it, the PCM solidifies at its freezing temperature and the energy (in form of heat) absorbed before can be released.

This is represented by the concept of latent heat (see the image nearby, courtesy of Rubitherm® Technologies). The latent heat is the energy released or absorbed, by a body or a thermodynamic system, during a constant-temperature process. This is the reason why a PCM is also referred to as a latent heat storage (LHS) material. These properties make PCM a reliable, consistent, and innovative solution for sustainable energy applications, where precise control of temperature is required.

Within the HYSTORE Project, Rubitherm® Technologies is particularly eager to develop and manufacture a modular storage system with a low-cost polymeric heat exchanger.