Harnessing Radiofrequency for Smarter Energy Storage: inovaLab’s Role in Hystore

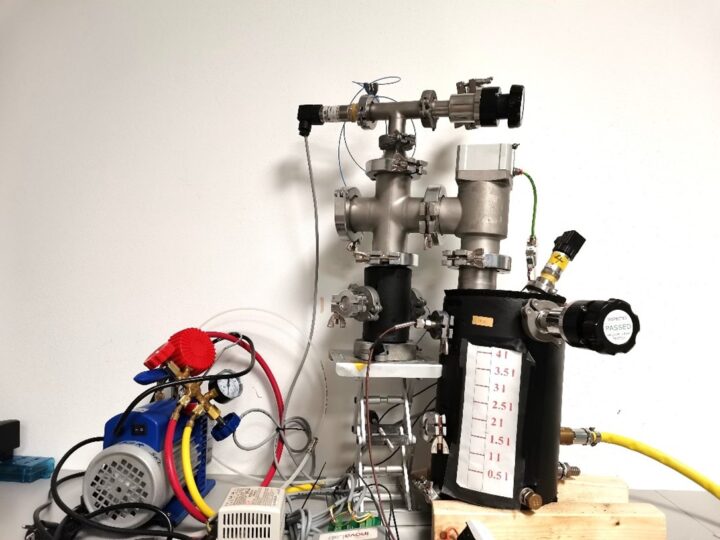

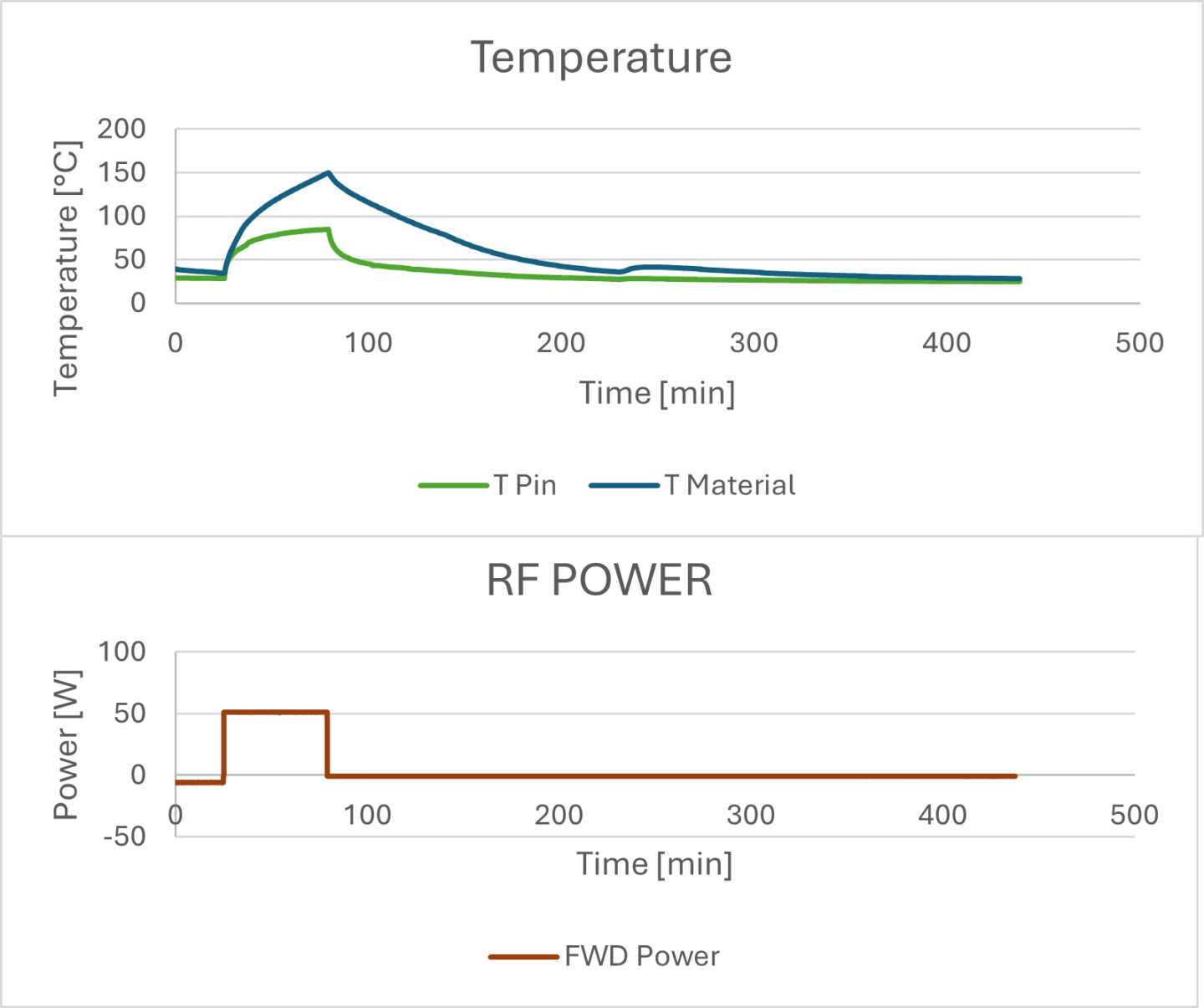

As a key partner in the Hystore project, inovaLab is applying its expertise in electrothermal technologies to enhance the TCM material charging phase. The team is focused on utilizing radiofrequency (RF) heating to efficiently remove moisture from the material in the adsorption/desorption chamber, optimizing its performance for thermal storage applications.

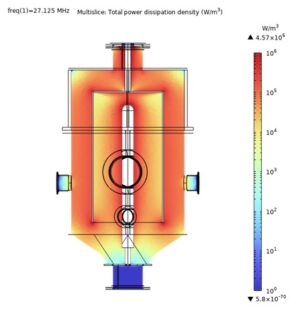

Through advanced simulations, inovaLab is designing an optimized electrode that will heat the material from within, ensuring uniform drying. Alongside CNR and SOR, the company is also contributing to the design of the chamber where this process will take place.

After validating the simulations through laboratory tests on a scale prototype, inovaLab is now progressing with electrode design and system verification for the Dublin pilot, followed by the Montserrat pilot.

Why RF Technology is a Game Changer

A key innovation in this project is the use of radiofrequency technology for drying dielectric materials in thermal storage systems. Unlike traditional conductive or convective heating methods—which act from the outside in—RF penetrates deep into the material, removing moisture from the inside out.

This approach offers two major advantages:

- Higher efficiency – RF interacts directly with the material’s structure, leading to faster and more uniform drying.

- Renewable-friendly – Since RF drying is powered electrically, it can be integrated with renewable energy sources. This enables storing surplus renewable energy by drying the material when production is high and using the stored energy when supply is low—helping to balance energy demand and supply.

By introducing RF drying into the Hystore project, inovaLab is pushing the boundaries of sustainable energy storage.

InovaLab: Innovating Electrothermal Technologies Since 2004

Founded in 2004 as a spin-off from the Laboratory of Electroheat of Padua (LEP), inovaLab specializes in enhancing industrial processes through cutting-edge electrothermal technologies. The company’s expertise spans induction heating, radiofrequency (RF) heating, and microwave (MW) heating, which are applied to develop sustainable solutions across multiple sectors, including:

- Food processing

- Domestic appliances

- Metallurgy

- Packaging

- Energy storage

Committed to customized R&D services, inovaLab offers material analysis, prototyping, and feasibility studies through numerical simulations and laboratory testing. The company’s mission is to drive innovation and sustainability, helping industries achieve greater efficiency and effectiveness.

With a dynamic, multidisciplinary team, inovaLab thrives in collaborative environments, making it an ideal partner for EU-funded projects like Hystore.

Stay tuned as inovaLab continues shaping the future of thermal energy storage with RF technology and electrothermal innovation!

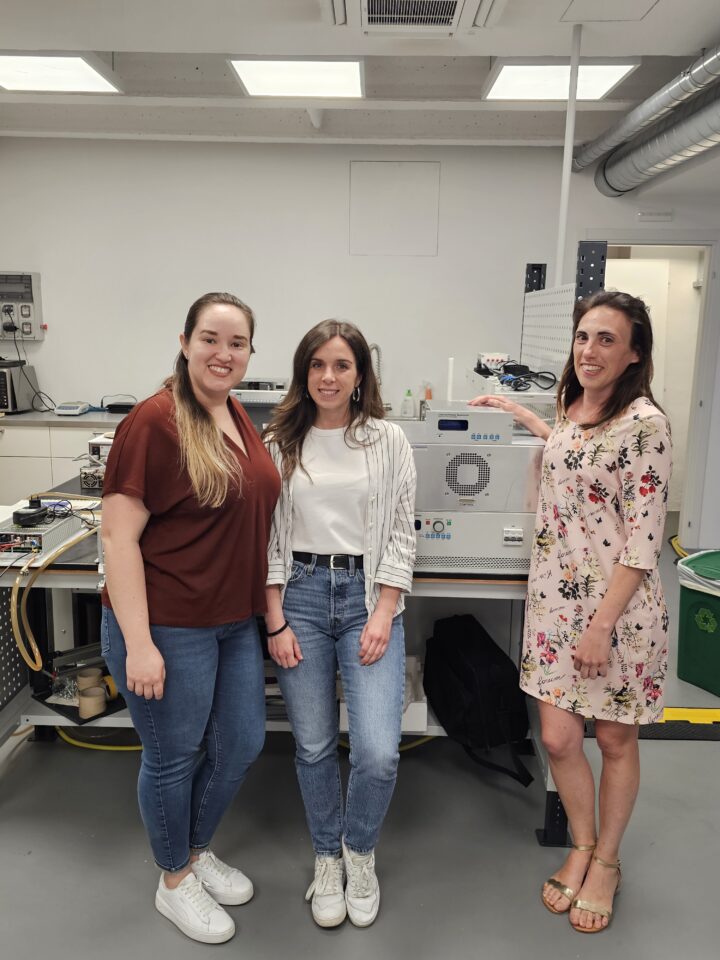

Discover who is involved from Inovalab:

Chiara De Masari

Chiara De Massari holds a Master’s degree in Electrical Engineering. She has been with InovaLab for nine years, working as an R&D Engineer specialized in microwave and radiofrequency processes; highly skilled in utilizing COMSOL software to simulate models representing real processes involved in electromagnetic fields.

Vanessa Garcia

Vanessa Garcia holds a Master’s degree in Physics and a PhD in Physics. She had a previous experience at INFN research centre and actually working in the R&D team of inovaLab, where she focuses on microwave and radiofrequency technologies. Vanessa is an expert in laboratory testing, specialized in interpreting and analysing results obtained from simulations conducted with the software Comsol.

Cristina Santoloce

Cristina Santoloce holds a Master’s degree in Energy Engineering. Currently working as an R&D Engineer at InovaLab, focusing on the electrification of industrial fossil fuels processes. She is specialized in optimizing thermodynamic processes to enhance energy efficiency.